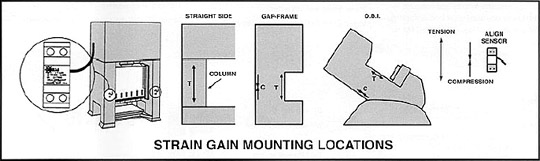

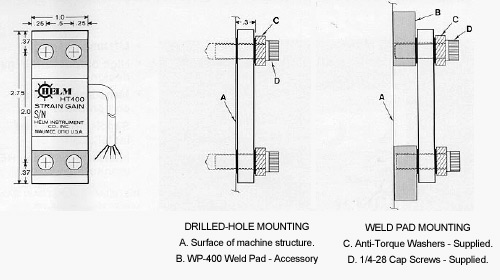

The HELM HT400 STRAIN GAIN load sensing transducer accurately detects strain levels on all types of metal stamping presses. Using either drill/tap or weld/pad mounting method, the sensor is installed directly to upright columns of straight side presses or throat area of OBI and Gap Frame presses. When interfaced with HELM monitoring systems, linear output of strain levels at each sensing location are displayed on digital meters.

Strain gages in a 350 ohm full wheatstone bridge circuit are used as load sensing elements to assure long-term stability and accuracy. Manufactured under laboratory conditions, all HT400 sensors are machined within 1% and may be interchanged without recalibration of the press.

| Capacity | 400 Microstrain |

| Overload | 600 Microstrain maximum |

| Recommended Excitation | 8 volts AC or DC |

| Maximum Excitation | 15 volts AC or DC |

| Output | 1 mv/v @ 400 Microstrain |

| Cable | Shielded 4 conductor cable with oil resistant polyurethane jacket |

| Size | 1″ wide x 2 3/4″ long x 5/16″ thick |

Standard STRAIN GAIN sensor is supplied with 35 feet of cable (Model HT-400-35), four mounting screws, two anti-torque washers, and hex wrench. Special cable lengths and complete installation kits for use with HELM load monitoring systems are also available. Consult HELM for details.

For drilled-hole mounting, DF-400 drill fixture is required.

For Weld-Pad mounting, WF-400 weld fixture and one set of WP-400 weld pads are required.

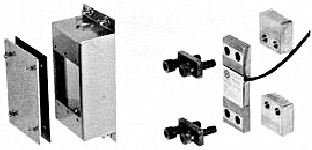

DF-400 Drill Guide

DF-400 Drill Guide

WF-400 Weld Fixture

WP-400 Weld pad (set)

T-21 Protection box

WS Cover with gasket