Get Quote | Standard Features | Alarm Features | Data Acquisition Features | Machine Output Adjust Features

PTM-ATG-200 | Compression Force Monitor

A Compression Force Monitor for Pharmaceutical Tablet Presses

- Proven Strain Gage Sensor Technology

- Accurate Compression Force Readings

- Long Life

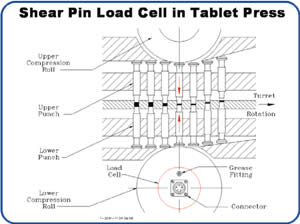

- Shear Pin Configuration

- Replaces Existing Yoke Pin For Lower Compression Roll(s)

- 15T Capacity Rating; Other Sizes Available

- Precision Machined and Heat Treated Stainless Steel Cell Body

- Integral Grease Fitting For Compression Roll Lubrication

- Integral Plug-In Connector with Mating Cable

- Factory Calibration

- Machine Protection

- Tooling Protection

- Tablet Weight & Density Control

- Tablet Height Control

- Detection of Table Forming and Ejection Problems

- Machine Set-Up & Adjustment Capability

- SPC Data Acquisition Capability

Standard Features

- Suitable for single(1) and dual(2) compression station machines

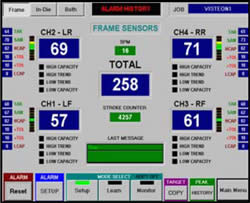

- Two channels of continuous strain gage main compression roll peak force monitoring

- Expandable to additional channels, for part ejection & pre-compression roll monitoring

- Proven PTM module strain gage signal conditioning

- 12″ color touch screen panel PC, with Ethernet for optional remote monitoring

- Display and monitoring of calibrated peak compression roll forces for each tablet (2 stations)

- Machine RPM & PPM display, with parts counter

- Adjustable high/low alarms for both channels, with alarm relay

- Separate proximity switch timing input for each channel, per staggered roll timing

- Job recipe storage for 250 jobs

- On-line SPC data collection

- Ethernet communications port, for optional remote monitoring at computer

- Tablet weight & tablet height feedback adjustment outputs (0-10VDC)

- Housed in rugged steel NEMA. enclosure, with keylock door (Note: Stainless steel waterproof enclosure available as option)

Alarm Features

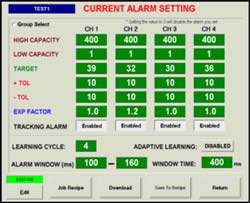

- Good part trend sampling routine, to arrive at an average learned force benchmark for each channel

- Adjustable high & low percent tolerance alarms for each channel, based on good part benchmarks, for tool protection

and tablet quality - Adjustable discreet high & low capacity alarms on each channel for machine protection

- Dry contact latching alarm relay output, activated by any alarm condition

Data Acquisition Features

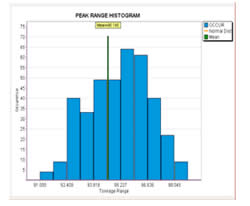

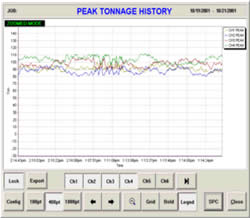

- On-line SPC data collection & display of peak tonnage values for each station

- Store up to 40,000 points per station of individual, average, median, range, and standard deviation

- Automatic storage of the last 200 load signatures

- Ability to overlay and display multiple signatures

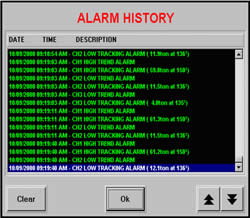

- Automatic storage of last 1000 alarm conditions, with date & time stamp

- Downtime reporting, with programmable downtime event for each condition

Machine Adjust Output Features

- 0-10VDC analog feedback output signal for 2 separate tablet weight cam adjustments, force based to maintain proper compression roll force

- 0-10VDC analog output signal for 2 separate compression roll tablet height adjustments, job recipe based

- Tablet weight cam & compression roll adjustment actuators to be furnished by customer