Incredibly Simple, Simply Incredible

One compact monitor for all machine types – from single blow headers to multi-station formers.

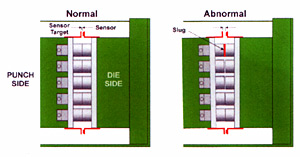

Frame mounted proximity sensorsused by the cold heading monitor detect variations in ram position at front dead center. Machine stop is initiated if off-tolerance condition occurs.

| Power Requirements: | 100-240 VAC, 50 or 60 Hz |

| Power Consumption: | < 15 watts |

| Output Contacts: | 2 NO-NC relays for machine and counter control |

| Output Contact Capacity: | 250 VAC @ 5 amps |

| Counter Timer Relay: | Adjustable from .5 to 25 seconds in .1 second intervals |

| Response Time: | < 10 ms |

| Sensor Type: | Proximity 200 kHz |

| Detection Range: | 1mm – 3mm |

| Repeatability: | .00004 inches (1/1000mm) |

| Alarm Adjustments: | Adaptive learn 0-500 Microns; Trend display 0-99 Microns |

| Parts Counters: | Preset (to 8 digits) Actual (to 8 digits) Batch (to 3 digits) |

| Operating Speed: | Up to 1200 RPM |

| Operating Temperature: | 0° to 50° Celsius |

| Display: | LCD with backlight (128 x 48 pixels) |

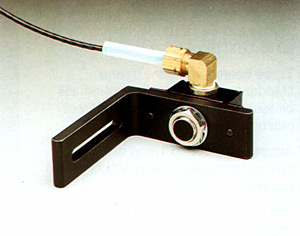

Each TMG-1200 Cold Heading Displacement Monitor is supplied with mounting bracket, DM-315 Installation Kit and instruction manual. The system is available for delivery from stock.

DM-315 Installation Kit for the cold heading monitor include two proximity sensors, adjustable mounting bracket, junction box and oil tight fittings.

Automatic Quality Control

Applications for the Cold Heading Monitor