PAC-10 Features

- 8 Die monitoring inputs

- 12 Programmable outputs

- 9 Job memory

- Shut height display

- Brake monitors

- Accumulative clutch counter

- Light Curtain interface

- Programmable security codes

- Fault history

PAC-10 is a full function automation controller that combines multiple functionality with a very user friendly design. As a resolver based system, the PAC-10 will fully automate and control your mechanical stamping presses.

Selectable PLS Outputs

Job Set-up

Shut Height Display

Die Monitoring Outputs

Counters

Password

Add two or four channels of tonnage monitoring to the PAC-10 with the Helm PTM-1 signal conditioning module. This din rail mounted module supplies 0-10 VDC output to the PAC-10 controller.

| Power Supply: | 24vdc 1amp |

| Temperature: | 0-50 °C |

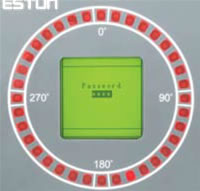

| Display: | LCD: 128 x 128 Angle display: 0-359° Screen resolution: 1° Max speed: 1,000 spm |

| Indicating lamps: | 36 angle 22 status |

| PLS settings: | 1-359° |

PM03 MODULE

| Input channels: | 24 Input voltage: 24 vdc Max input current: 20 mA |

| Output channels: | 16 transistor outputs Supplied voltage: +24v Output voltage: +24 Max output: 0.5A |

CRANK ANGLE RESOLVER

| Voltage frequency: | 7Vrms 10KHz |

SHUT HEIGHT INCREMENTAL ENCODER

| Power supply voltage: | 12V DC |

| Response frequency: | 0-100 KHz |